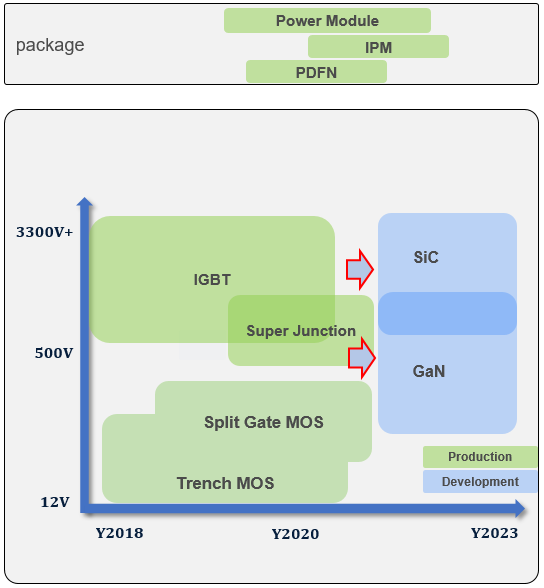

Technical Introduction

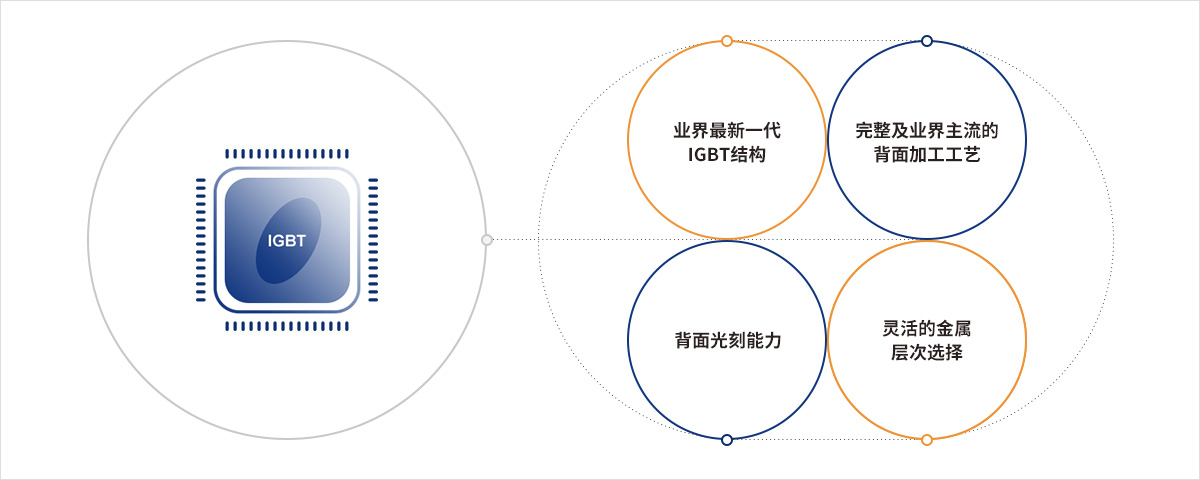

Based on field Stop IGBT structure, UNT adopts advanced backside process technology, including backside thinning process, ion implantation, laser annealing and special metal deposition process. 600V~1200V process platform is already in mass production. UNT provide specific FRD wafer foundry service as well.

Characteristic

Field Stop IGBT structure, advanced backside processing technology and flexible metal layer selection can provide customized process development and mass production solutions for customers.

Applied Products

Customers’products are widely used in consumer electronics, industrial invertors and convertors, home appliances, electric vehicles, smart grid, wind power and solar energy and etc.